BBC Cellpack Cold shrink technology

Cold Shrink “All-in-One”Straight Joints (CCMSV) | For polymeric insulated cables up to 18/30 (36) kV | Type-tested according to the latest HD 629.1 S3:2019 standards

Cold shrink technology for medium voltage

In addition to hybrid-heat shrink and cold slip-on solutions, BBC Cellpack Electrical Products now also offers cold shrink “All-in-one” joints. This complete range of products for medium voltage (MV) applications, we provide our customers, the flexibility to choose the product that best suits their application.

The cold shrink joints are manufactured using highelasticity liquid silicone rubber (LSR), which offers excellent insulation and high flexibility. The use of Silicone rubber offers many advantages: it exerts

constant radial pressure on the contact surface, has high tear strength and high hydrophobicity, and is chemically inert and flame-retardant.

“ALL-IN-ONE” COLD SHRINK JOINTS (CCMSV)

The cold shrink joints have been type-tested according to the latest CENELEC HD 629.1 S3:2019 standard which guarantee reliable connector connection, excellent stress control and adequate

insulation to ensure operational safety and high network reliability.

The joints are suitable for all 1-core polymericinsulated cables with copper wire and tape screen up to 18/30(36) kV. They allow the connection of cables with different cross sections and conductor

materials, and even different semiconductive layers.

Installation is simple, fast, and easy.

FEW

SYSTEM

COMPONENTS

INTEGRATED

STRESS-CONTROL

ELEMENTS

CONSTANT

“RADIAL PRESSURE”

ON THE CABLE

RANGE

TAKING

PRODUCT

NO SPECIAL TOOLS

NEEDED FOR

INSTALLATION

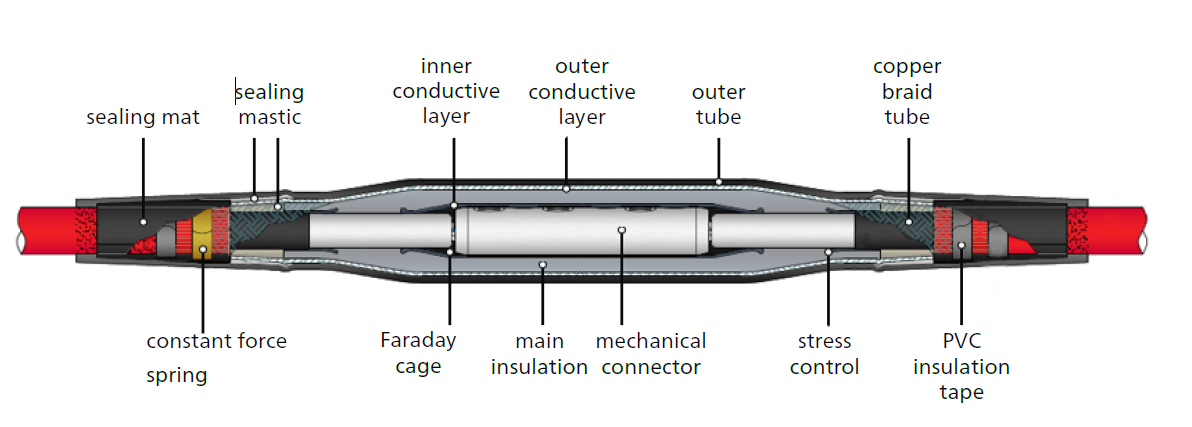

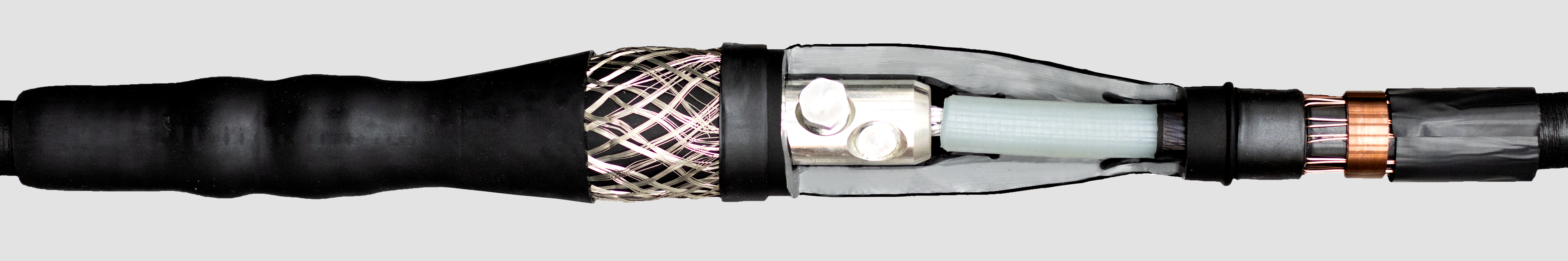

The mechanical connectors offer a perfect fit in the CCMSV joints. These connectors are made of tinplated aluminum alloy suitable for different conductor materials (aluminum/copper) & shapes (RE, RM, SE, SM).

- Pre-set torque ensures smooth shearing off the bolts when tightened

- Internal grooves & off set arrangement of bolts ensure optimum contact of the conductor

- Chamfered ends guarantee easy and damage-free slipping of the silicone body

- Type-tested according to IEC 61238

- Centering inlays pre-installed with easily removeable option – offers a perfect fit for conductors

[Translate to English_IN:]

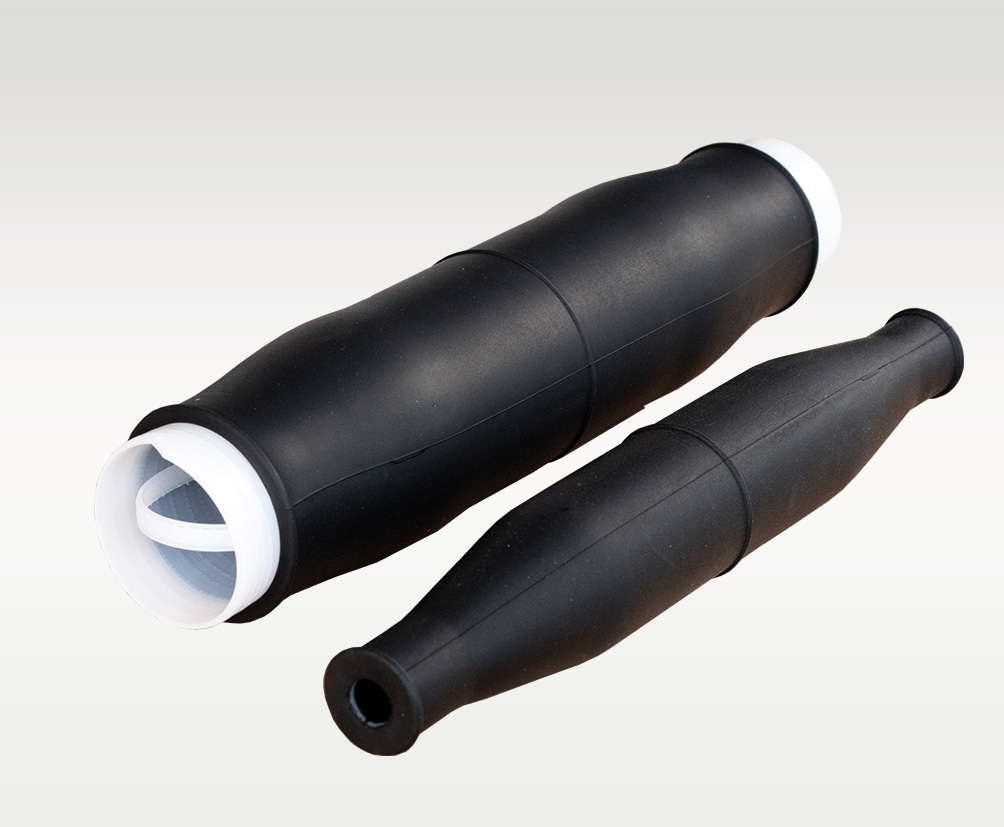

The insulation body is made of high-performance silicone rubber and factory expanded onto a spiral holdout system providing a suitable diameter clearance for easy positioning over cables and connectors.

This one-piece insulation body provides stress control, insulation, and insulation screen to rebuild the cable structure. Silicone rubber, with its amazing electrical and mechanical properties, offers:

- High dielectric strength

- Wide x-section range (thanks to high elasticity of silicone)

- Excellent sealing property (hydrophobic)

The special shape of the joint-body implements the geometrical stress control principle, which regulates the electrical field at the cable ends (screen cut area). The inner conductive layer of the joint body forms a Faraday cage in the connector area, which ensures stress control and makes the use of further components unnecessary.

The electrical screen continuity of the cables is achieved by means of a copper stocking pre-installed over the joint body. Electrical continuity between the cable screen and copper stockings is achieved by using austenitic-steel constant-force springs. The copper stocking has a cross section of 25 sq.mm and is compatible with both tape and wire screens.

- Solder-free electrical connection of metal cable components

- No tools required for screen continuity

The outer protection, pre-expanded and pre-installed over the joint body, is made of siliconee rubber because of its excellent mechanical & chemical properties. The outer tubes, together with the mastic tapes, offer excellent sealing & prevent water penetration during the operation.

- Hydrophobic

- Chemically inert (resistant to chemical solvents, fuels, oils, etc.)

- Flame-retardant, fumes non-toxic when it burns

- Performs better than other polymers in harsh environments (anti-UV, anti-aeging, etc.)