-

-

There is currently no approval for use in areas subject to explosion hazard.

-

-

As long as only the cable sheath (external plastic) has been damaged, the insulation tape can be used as a temporary protection. It does not create a secure seal against moisture. However, if the base insulation is also damaged, simple insulation tape is no longer sufficient. In this case, it is recommended to use a gel, cat resin or heat shrinkable cable joint. The same applies to damages to the core.

-

-

Hereby we inform you that our products contained SVHC substance lead (CAS 7439-92-1) with concentration higher than 0.1% are now registered in SCIP database at ECHA (European Chemicals Agency). Those products contain aluminium and/or copper alloy in our connecting technology and are mentioned in BBC Cellpack REACH-Declaration of conformity regarding Regulation EC/1907/2006 from 28.02.2022, the products can be sold. The SCIP database number is protected by Data Protection Law and is not listed here.

The reason for the registration in SCIP database is described in Directive (EU) 2018/851, paragraph 38: “When products, materials and substances become waste, the presence of hazardous substances may render that waste unsuitable for recycling or the production of secondary raw materials of high quality. Therefore, in line with the 7th Environment Action Programme, which calls for the development of non-toxic material cycles, it is necessary to promote measures to reduce the content of hazardous substances in materials and products, including recycled materials, and to ensure that sufficient information about the presence of hazardous substances and especially substances of very high concern is communicated throughout the whole life cycle of products and materials. In order to achieve those objectives, it is necessary to improve the coherence among the law of the Union on waste, on chemicals and on products and to provide a role for the European Chemicals Agency to ensure that the information about the presence of substances of very high concern is available throughout the whole life cycle of products and materials, including at the waste stage”.

-

-

BBC Cellpack's polyurethane-based sealing compounds are susceptible to petrol, which can affect their properties.

-

-

Organic fertilisers are composed of different chemical substances, such as ammonia or nitrate in varying concentrations. As a result, it is not possible to carry out a meaningful test of the sets with regard to organic fertilisers.

-

-

Gasoline resistance depends on the type of gasoline. On the market there are different types of gasoline on the market, which are mixed with ethanol or other substances, and each gasoline has a different chemical structure and reacts differently with the resin system. Therefore, the particular type of gasoline should be should be tested according to the requirements and applications of the products.

-

-

End joints and branch joints for medium voltage are not included in the BBC Cellpack product range.

-

-

The gel joints from the EASYCELL®, EASY-PROTECT and EASY-PROTECT Inline product range are designed for single use only.

-

-

The SHE house connection point is not suitable for feed-through in floor slabs.

-

-

All cast resins and shrink systems are suitable for sea water. However, they are not directly tested with the common test standards.

-

-

The self-sealing tapes with UV stabilisation offered by BBC Cellpack are specified in the overview table in the catalogue.

UV-resistant is generally used as a colloquial term to indicate that the properties of a material do not change at all or not significantly due to UV irradiation. UV-stabilised specifies relevant ambient conditions (e.g. (e.g. irradiance and irradiation duration). UV irradiation can alter the properties of the tapes within acceptable limits.

-

-

To create a safe electrical connection, a minimum distance of 5 mm is compulsory for low voltage (up to 1 kV) between the terminals / cores and plastic shell and/or housing of the branch box. This 5 mm distance also applies to gaps between individual non-insulated connectors. Individual measurement sin the BBC Cellpack assembly instructions may vary according to product.

-

-

The joint can be used straight after casting and/or when live. The relevant provisions “Working with live parts” must be complied with.

-

-

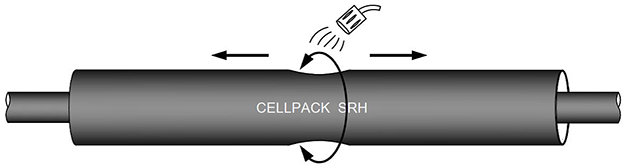

Heat shrinkable components are components that shrink back to their original production state when heat is applied, such as spreader caps, end caps, hoses, or sleeves. A hot-air blower can be used for shrinking. The heat input, however, is lower compared to a gas burner. This prolongs the duration of the shrinking process. The settings and nozzle must be individually selected depending on the hot-air blower used. It is important to make sure that the surface of the shrinkable tube is not burned.

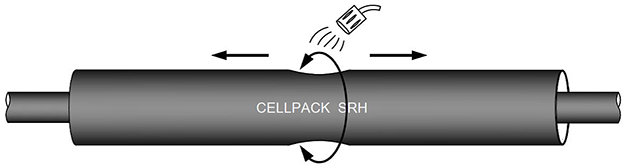

If it is a hose with hot melt adhesive (SRH...), the adhesive will slowly flow out at both ends. Uniform wall thicknesses and straight labelling are important indicators for correct shrinkage.

-

-

The formulas of most 2-component cast resins have components with different properties. Using the cast resin within the best-before date guarantees safe handling and ensures that the functions work properly when used properly. The mixture may still work once the best-before date has been exceeded. However, the properties may deviate.

-

-

The EASYCELL joints can be mounted in a range from -10°C to +60°C. As with all other joints, care must also be taken that there is no moisture in the entire gel joint area, snow and ice included.

-

-

Compatibility table

of separable connectors from BBC Cellpack with cone voltage sensors (IEC 61869-11)

Connector type | Sensor type | Manufacturer | Art. Nr. | Installation Depth mm |

CTS 630 A 24 kV | KEVA 24 C25c

(IEC 60044-7) | ABB | 371530 | 276 |

KEVA 24 C25c

(IEC 61869-11) | ABB | 371536 | 276 |

KEVA 24 C25c (without semi-conductive surface) | ABB | Direct purchase from ABB | 276 |

| SMVS UW 1002-2 | Zelisko | Direct purchase from Zelisko | 287 |

| RDP4-24 | Hortsmann | Direct purchase from Hortsmann | 287 |

CTS & CTKS 630 A 24 kV and CTS & CTKSA | KEVA 24 C25c

(IEC 60044-7) | ABB | 371530 | 392 |

KEVA 24 C25c

(IEC 61869-11) | ABB | 371536 | 392 |

| KEVA 24 C25c (without semi-conductive surface) | ABB | Direct purchase from ABB | 392 |

SMVS UW 1002-2 | Zelisko | Direct purchase from Zelisko | 401 |

RDP4-24 | Hortsmann | Direct purchase from Hortsmann | 401 |

CTS-S 630 A 24 kV | KEVA 24 C10 (without semi-conductive surface) | ABB | Direct purchase from ABB | 283 |

KEVA 24 C10c | ABB | Direct purchase from ABB | 283 |

| SMVS UW 1001 | Zelisko | Direct purchase from Zelisko | 269 |

| RDP1-24 | Hortsmann | Direct purchase from Hortsmann | 269 |

03816695N0 (24 kV)

03816686N0 (12 kV) | Schneider Electric | Direct purchase from Schneider Electric | 269 |

Reference:

1. For the installation of voltage sensors following kit shall be ordered Art.-Nr. 391083 additionally.

2. Installation depth is length between the bushing and the door of the switchgear. If the overall length of the separable connector with installed cone voltage sensor will be longer than allowed installation depth, which depends on switchgear, then the door of the switchgear can’t be closed.

| To which IED will it be connected? (Model & brand) | → | IEC 6004-7 or IEC 61869-11? | → | What is the transformation ratio? | → | What is the burden? | → | IED’s connector type? | → | Length of the secondary cable? | → | What is the maximum installation depth? | → | Depth Ok? | → | Choose your Option |

-

-

This generally does not prove a problem as long as the housing has been sealed when casting and/or the cat resin cannot escape after the casting until it has hardened.

-

-

If the DR-L connectors have a second crimping point in the component application, they can be used on solid conductors. Since the DR connectors are designed shorter and only allow one crimping point, the component application cannot be used for solid conductors. The common crimping pliers have 2 crimping points in the jaws, i.e. on the DR-L, the pliers are applied 2x for left and right. On the DR, the pliers are pressed on both sides with 1x pressing operation. The EASY-FIX system application is in turn available on solid conductors.

(Component application = direct reference to the crimp connector)

-

-

As there are a multitude of crimping pliers, this application primarily depends on the tool used.

We therefore recommend to check and approve this application yourself.

-

-

All EASYCELL® joints are tested in accordance with test standard DIN EN 50393. This standard requires for the load to be changed with 0.1 bar water pressure. This means that the joint can be used in water depths of up to 1m. The assembly specifications must be complied with at all times. Deeper applications can be agreed with the manufacturer, but have to be tested separately

-

-

The test adapters are exclusively intended for use in threaded shielded T-shaped EPDM cable connections of the types CTS and CTKS. It is not allowed to use the screw inserts in cable connectors from other manufacturers.

-

-

Conductive outer layer of the body of EPDM absorb UV radiation and, in most cases, there is UV-exposure which leads to partly surface aging at the border of material with outside atmosphere. Due to this feature of the material, damage of deeper layers through UV-exposure is not expected. The usage of UV-stabilized PVC band (e.x. No. 328) on the cable entry is recommended.

-

-

Such joints cannot be subsequently filled with cast resin, since proper casting cannot be guaranteed. (Various environmental conditions, such as temperature, humidity or dirt affect the result. These conditions have not been checked.)

-

-

Our joints go through extensive tests, such as test standard DIN EN 50393. We thus guarantee that our joints function permanently and are safe. We seriously discourage you from making your own joint so that you do not have to assume responsibility.

-

-

Thanks to their design, the joint shell and the associated branch-off block are suitable for one continuous main cable and one branch cable.

-

-

Screw connectors CSV-LHS & CSV-T and screw cable lugs CSK from BBC Cellpack are made of aluminium alloy. Within electroplating process the complete surface (inside and outside) is tinned. Tin is a typical coating material, applicable for both Al and Cu parts, which make direct contact between aluminium and Copper parts possible without additional handling. Please be aware that tin layer should not be damaged. This is state-of-the-art technology, being used by all main producers of screw connectors and cable lugs in Europe.

-

-

Public swimming pool water contains a certain concentration of chlorine. This point falls under the term “resistant to chemical effects”. This means that tests with the actual chlorine content and/or composition of the water (e.g. thermal water) are necessary. Of course it has to be assumed that the components have been properly assembled and used as specified.

-

-

The BBC Cellpack sets have not been certified for drinking water.

-

-

It has to be remembered that the cable cross-section and minimum diameter across the insulation falls within the specified range for the set. The reverse is excluded. In most cases, the applicable system voltages are specified in the documentation available and provided.

-

-

The contact pin can be removed with a long socket, which makes it possible to reuse it. We recommend using an additional set, because the surfaces are both cleaned and the lubricant GM1 must be reused. It is also important to ensure appropriate air-release during installation on the feed-through and the termination insert. The required torque is available on request.

-

-

Yes, EASYCELL 3V, 4V and 5V can be combined with CU conductors and AL conductors, since they have a tin-plated connection block with separator.

-

-

This use is generally possible. However, it has to be ensured that sufficient gel is displaced. This means that both gel surfaces must close around the cable end to ensure a seal against moisture.

-

-

It can be used according to the compatibility table. The cross-sectional area deviates from the current standard products.

Download Overview

-

-

The screw cable lugs of the connector product range are not suitable for this application. This type of cable is very special and requires deeper inspection for suitability.

-

-

The responsible person in the network is responsible for deciding whether a cable sheath can be repaired. This depends on the damage and the properties the cable sheath satisfies. In general, a cable may only be repaired with a sleeve if the damage affects only the outer cable sheath. If additional damage to the core insulation is detected, repairs by means of a sleeve are not permitted. The cable must then be repaired as a complete system, either with additional insulating and sealing components over the damaged core(s) or, if necessary, by installing a straight-through joint over the damaged cable section.

If it decided to use shrinkable sleeves, the sleeve should be selected according to the values mentioned in the catalogue. The operating voltage of the cable is not the deciding factor when selecting the right sleeve. The function of sleeves is described as follows - restoration of the outer cable sheath in its three functions insulation, protection against moisture and mechanical protection.

-

-

Straight-through joints are designed for butt jointing two cables. Branch joints, on the other hand, are intended for a main conductor (which is not cut) and an outgoing cable. It is very difficult to join all three cable ends in one joint due to the lack of volume inside the shell and the need for special connectors. In addition, BBC Cellpack's standard joints were not designed for this application. We recommend using the following constellation to ensure a reliable and secure connection:

One exception to this rule are the two cast resin branch joints T1/EG/V/WAGO and Y1/EG/V/WAGO. They can be used to connect or branch three cable ends with up to 5x 0.5mm² - 5x 4mm² in one joint. The set contains 5 pieces of each WAGO COMPACT 221-413 series splicing connector.

-

-

The tensile strength of BBC Cellpack sets depends on the system used (e.g.: shell with mounting, screwed connection, tensile connectors). The standard for sets does not include a tensile test of the installed joint. The standard for compression and screw connectors refers to DIN EN 61238-1, which describes the requirements for mechanical testing. A strain relief implies that no tensile forces are applied.

-

-

Cellpack SR(H), SRAT, SRBB hoses do not contain chlorine (or any other halogen-containing materials), sulphur, heavy metals or substances that are hazardous to health. A corresponding RohS and Reach conformity confirmation is available for the respective component.

-

-

The BBC Cellpack gel products are made from cross-linked silicone. As soon as the silicone has cross-linked, the tolerance is not limited.

-

-

BBC Cellpack has different approvals and the list of them is changing, so if you need some special approval – contact us.

-

-

The conductor shapes are tested at the factory: RE (round, solid), RM (round, stranded), SE (sector, solid) and SM (sector, stranded). Connectors and cable lugs are approved for conductor class 1 (solid conductor construction) and 2 (stranded conductor construction). Compressed conductors (RMv and SMv) are also supported. There is no approval available for class 5 (fine stranded conductors) and class 6 (extra fine stranded conductors).

-

-

A cast resin joint can generally be used for this if the minimum distances are complied with. It is a little more difficult, but generally possible, to seal the flat cable into the round infeed of the shell. Heat shrinkable and gel cable joints are less suitable for this job due to the flat cable.

-

-

BBC Cellpack's AK screw branch clamps are suitable for branching aluminium or copper conductors. To ensure that no parts are lost, we recommend that you only open the AK clamp after the cable ends have been prepared. This is done by stripping the main conductor in the contact area without cutting the conductor. The conductor of the branch is also stripped at the end and then placed above the main conductor. To open the AK clamp, remove the contact screw and the upper plastic half. The AK clamp is assembled in the reverse order.

Two aluminium or two copper conductors can also be connected, but aluminium and copper cannot be combined due to the design.

-

-

BBC Cellpack's FK overhead line terminals are suitable for branching copper conductors. To ensure that no parts are lost, we recommend that you only open the FK terminal after the cable ends have been prepared. This is done by stripping the main conductor in the contact area without cutting the conductor. The conductor of the branch is also stripped at the end and then placed above the main conductor. To open the FK clamp, remove the nut. The FK clamp is assembled in the reverse order. Two copper conductors can also be connected.

-

-

BBC Cellpack's KP branch clamps are suitable for branching copper conductors. To open the KP clamp, turn the screw to the end of the thread. The main cable and the branch cable are then positioned in the housing recesses provided for this purpose without stripping them. To assemble the KP clamp, the screw is tightened again, while the wires are contacted by the integrated cutting contact.

-

-

Pump lines are different from radial cables or lines due to their flat design and fine-stranded conductors (class 5) are also common. This is why the following must be observed when selecting and assembling the joint:

• Maximum number of cores 4 conductors per cable end.

• Spacer plates must be used to arrange the connectors. They are included with our M11, M12, M13S and M13 cast resin joints.

• The joint must provide sufficient space for the flat cable to be inserted (max. cable Ø mm).

• Suitable compression connectors and compression tools must be used.

• To make it easier to seal the flat cable to the plastic shell of the joint, we recommend using a sealing compound, such as our HKB mastic tape (item no.: 127651).

• For standardisation reasons, the water depth should not exceed 1m.

The assembly can be carried out as shown in the drawings:

-

-

There are different options:

1) Copper press cable lugs in accordance with DIN 46235 and aluminium press cable lugs in accordance with DIN 46239 are pressed using the hex method in accordance with DIN 48083. The press insert to be used depends on the external diameter, which is always stated on the component. The pressing process evenly deforms the individual cores, thus creating a stable electrical and mechanical connection.

2) If the cable lug is specific to a manufacturer (so-called tube cable lug), it is only permissible for the copper area and cable class 2 in accordance with DIN 60228 in most cases. In such case, the system specific to the manufacturer must always be used.

In both cases, the pressing process starts from the centre of the bore hole (as marked) and continues toward the cable. The pressing makes the connector a little longer. A pressing excess of 5 mm (Cu) and 10 mm (Al) is therefore accounted for when preparing the cable.

-

-

There are different options:

1) Copper press connectors in accordance with DIN 46267-1 and aluminium press connectors in accordance with DIN 46267-2 are pressed using the hex method in accordance with DIN 48083. The press insert to be used depends on the external diameter, which is always stated on the component. The pressing process evenly deforms the individual cores, thus creating a stable electrical and mechanical connection.

2) If the press connector is specific to a manufacturer (so-called butt splice-connector), the manufacturer’s instructions must always be complied with.

In both cases, the pressing process starts from the centre of the connector (as marked) and continues toward the cable. The pressing makes the press connector a little longer. A pressing excess of 5 mm (Cu) and 10 mm (Al) is therefore accounted for when preparing the cable.

-

-

For screw connectors with shear bolts, all bolts must be tightened in sequence during assembly.

If there are two bolts per cable side, the bolt toward the cable is then sheared off first followed by the bolt to the centre of the connector. For screw connectors with just one bolt each, these must be tightened evenly until shearing off.

-

-

Firstly, position the shrinkable tube. Initially set the blow torch to a soft yellow flame. Now start the heating process from the centre and radiating outward. Continue this movement whilst initially shrinking one full side. Now change back to the centre and repeat the process on the other side.

If the tube contains hot melt adhesive (SRH...), the adhesive slowly escapes at both ends. Important indicators that the shrinking process has been completed correctly are even wall strengths and straight labelling. Below is an image from straight-through joint assembly instructions:

-

-

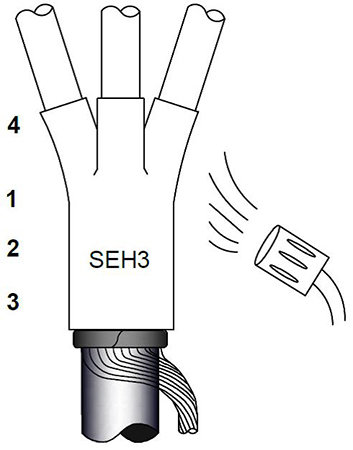

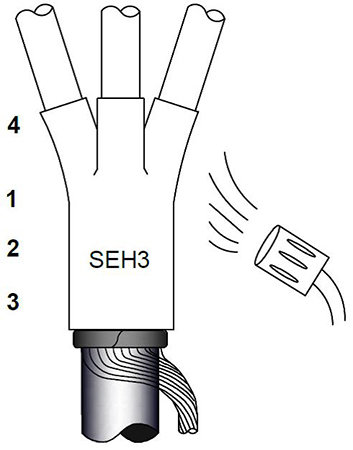

Firstly, position the spreader cap on the cable joint. Initially set the blow torch to a soft yellow flame. Now start heating up the interstice (1) radially. Continue this movement whilst shrinking the shaft (2+3) toward the cable sheath. Now change back to the shaft and evenly shrink the fingers (4) toward the core; also heat up the inside of the splice. The adhesive slowly escapes at the end of the shaft and the spreader fingers after a short period. Important indicators that the shrinking process has been completed correctly are even wall strengths and straight labelling.

-

-

Unused cast resin hardens in the bag. Once fully hardened and as long as components A and B have been fully mixed, it can be simply discarded with the residual waste.

-

-

A tube is initially extruded from polyolefin pellets. Depending on the type of tube, the hot melt adhesive is introduced in this step (co-extruded). The tubes are then electron beam cross linked. This changes the molecular structure and the tubes receive a “memory”. In another work step with heat supply, the tube is expanded to the required diameter, then cooled down and cut. When heating up, the tube “remembers” its original state and shrinks back.

-

-

This is used for easily feeding cables and cores through walls in buildings.

Simply put, it is a shrinkable tube that is positioned on a formative metal spiral. Once installed, the cable is pushed through the duct in the house and sealed by simply heating up the ends of the house duct. This is the assembly process:

First drill a hole through the brickwork. It is recommended to refer to the BBC Cellpack data sheet to ensure that the right drill bit with the right diameter is being used. The cable centering aid can be used for aligning the house connection point. When the distances are correct, the sealing compound can be prepared. Like the cast resin, it is mixed in a two-chamber bag but has a much quicker reaction time. A homogenous sealing is now created with a spatula. Due to the shorter processing time, a separate bag can be used for the inside and outside.

-

-

STEP 1: Ideally, the bag has a temperature of around 20 °C.

STEP 2: Before starting the mixing process, the separator between resin and hardener has to be removed. The sealed mixing bag makes contact with the two components impossible.

STEP 3: During the mixing process, both components must be mixed until one homogenous mass as best as possible. The times specified in the processing instructions, 3 minutes, must be complied with.

STEPS 4+5: It is not enough to simply sway or shake the bag. To prevent cast resin losses as much as possible, it is recommended to spread the cast resin from the corners and roll up the empty end.

STEPS 6+7: Afterwards, one corner of the bag can be cut open to pour the cast resin into the joint. Below is an image of the assembly instructions with the separate steps:

-

-

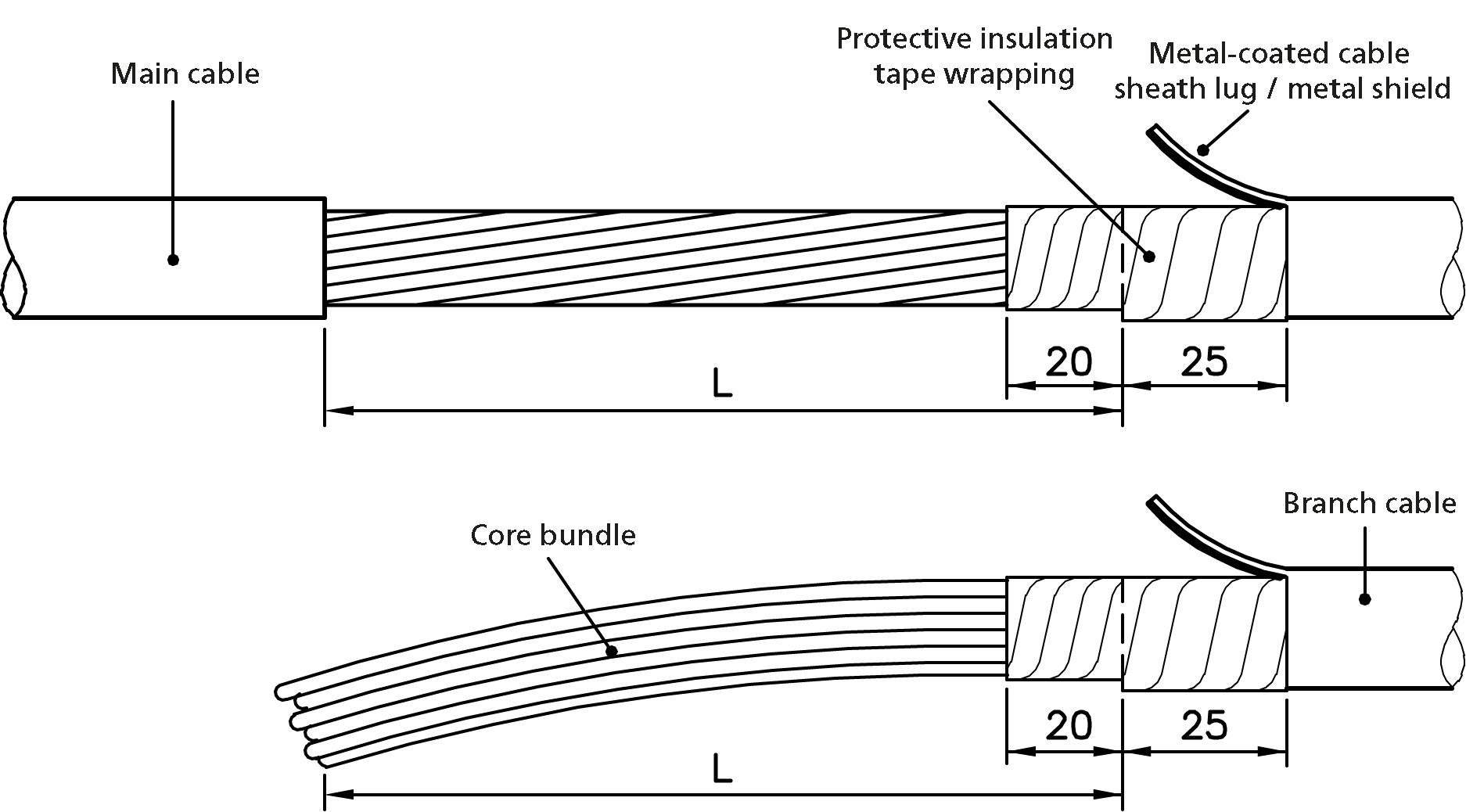

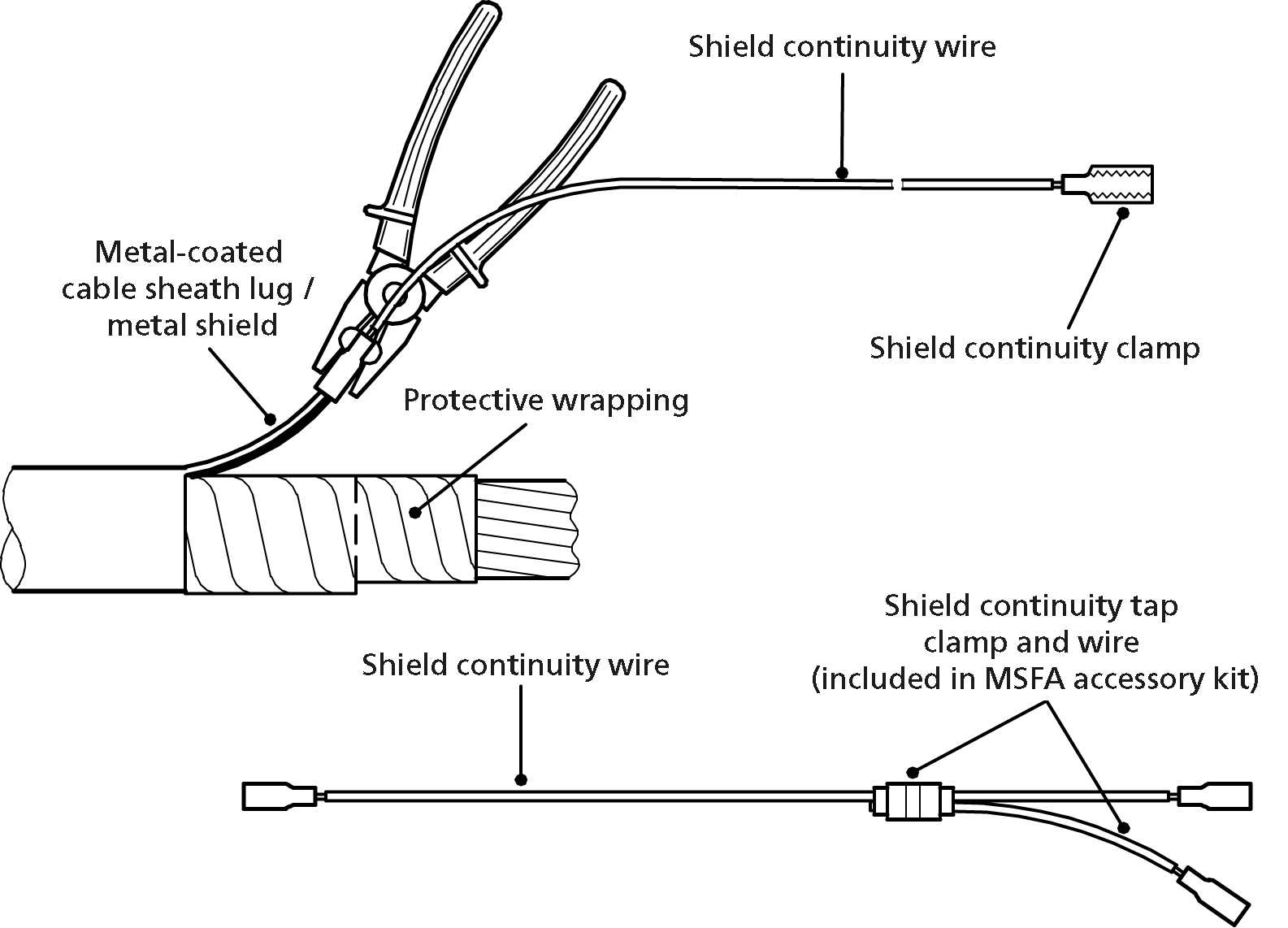

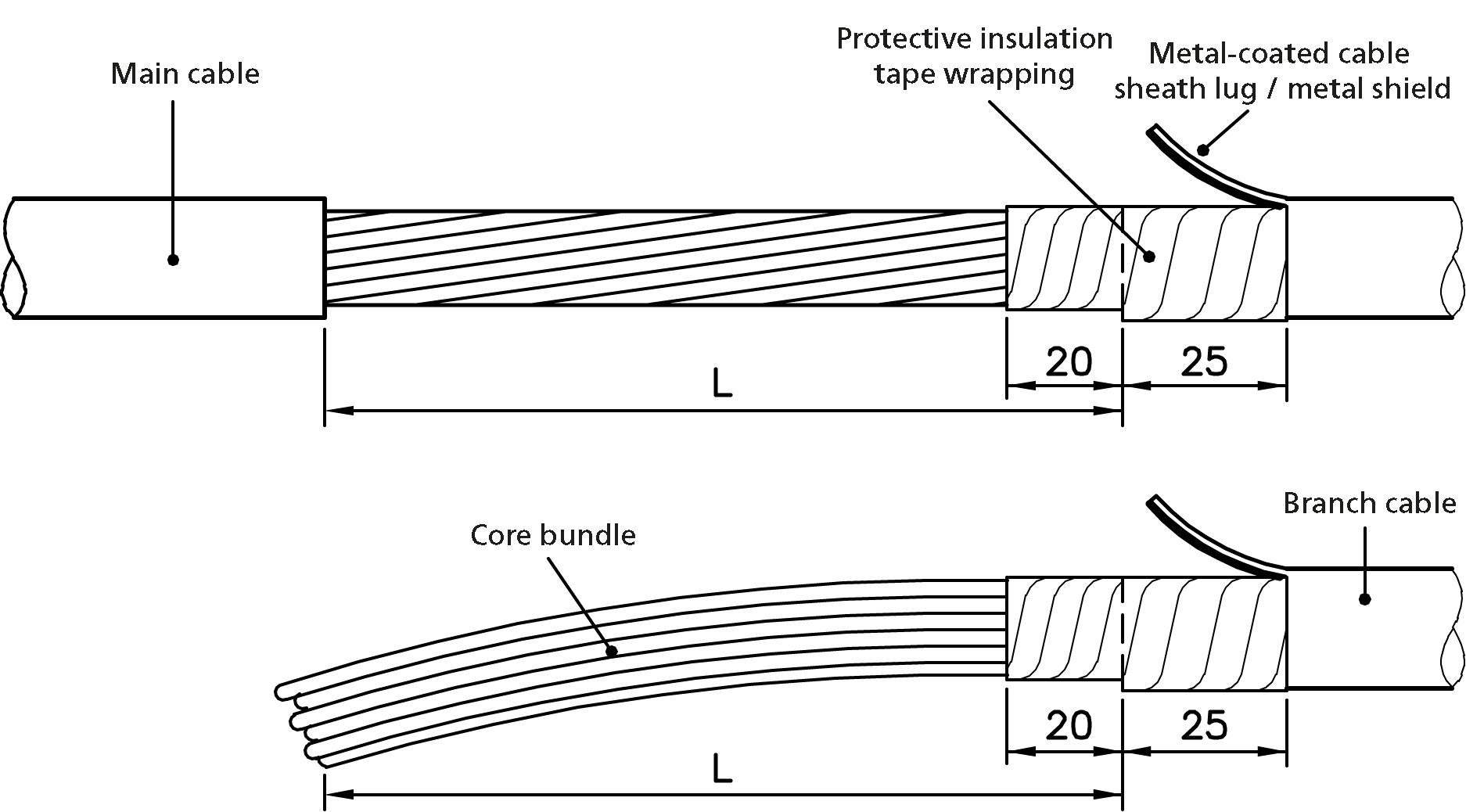

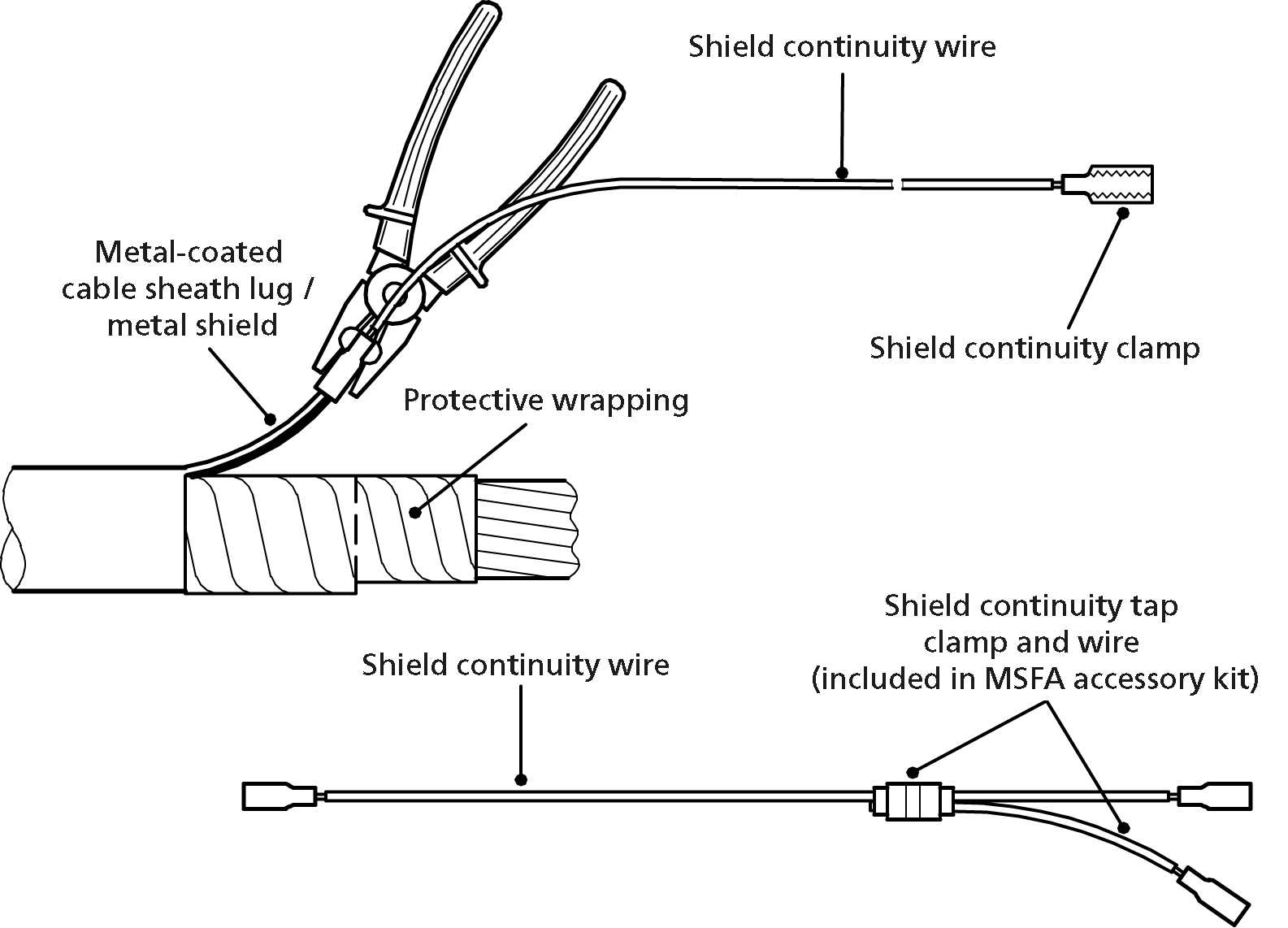

In the assembly instructions for the VASMI and SMHF telecommunication joints, this step is described as follows:

A) Preparing the cables

Overlap the cables as shown in drawing:

The cables are prepared exactly like the straight-through joints, depending on cable type.

B) Screen connection

Create screen connection like the straight-through joint.

Assemble screen connection branch clamp and wire (take from MSFA and assemble according to the assembly instructions).

The MSFA accessories set is only required for branch joints.

-

-

During the kneading process, the resin and hardener are mixed and start an exothermic chemical reaction. The assembly instructions provided show a bag mixing time of 3 minutes. If the mixing time is shorter, the components are not sufficiently mixed. Contrary to popular opinion, the cast resin does not “dry”; if the reaction cannot occur, the mix will not harden. The electrically and mechanically required properties are not met in this case.

-

-

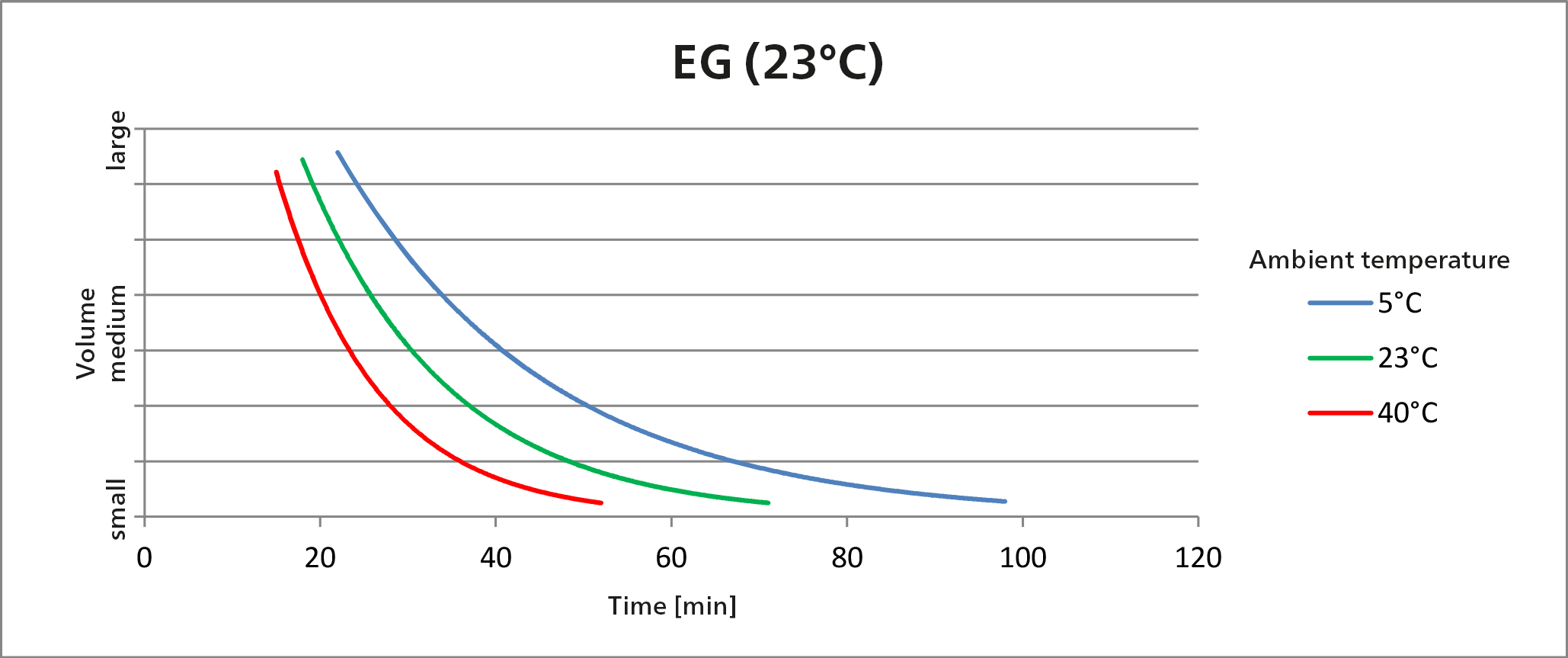

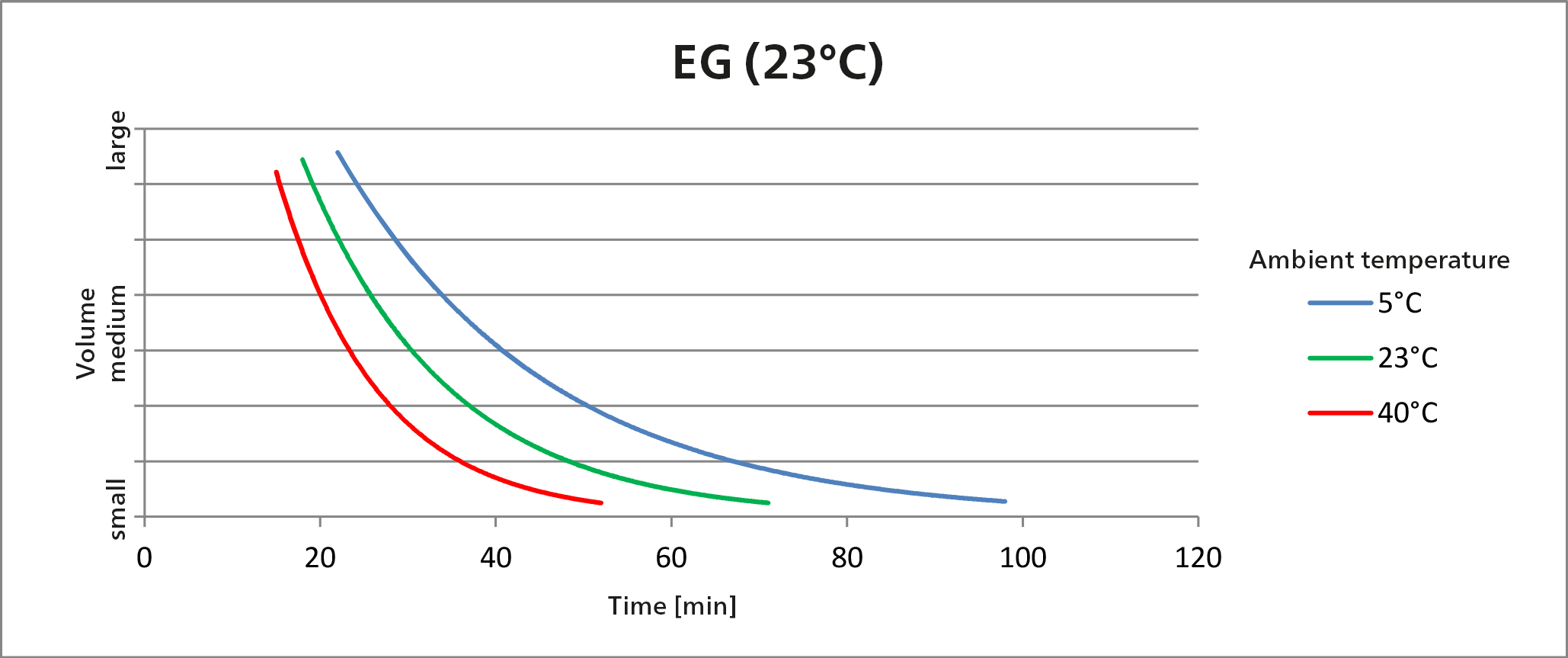

The hardening time of the liquid EG cast resin depends on the ambient temperature, component temperature and cast resin volume. The following diagramme contains more information on this topic:

-

-

Pollution impact is not an issue for screened separable connectors from BBC Cellpack Electrical Products in contrast to unscreened separable connectors or heat-shrink terminations. Following separable connectors: CTS, CWS, CTKS, CGS, CTS-S can be used in environment with different pollution classes.

-

-

The EASYCELL joints can be installed in a range from -10°C to +60°C.

After installation, the joints can be operated in a temperature range from -20°C to +90°C.

-

-

The heat shrinkable kits offered by BBC Cellpack are suitable for concealed installation. We do not recommend using individual tubes without hot-melt adhesive, since in this case, there is no protection against the penetration of moisture and the insulating function of the hose over the offset cable cannot be fulfilled.

-

-

Conductive outer layer of the body of EPDM absorb UV radiation, due to this feature of the material, damage of deeper layers through UV-exposure is not expected. Cable adapter made of EPDM is allowed for outdoor usage.

-

-

No, this is not recommended. The lubricants are assigned to specific cable accessories. Most have electrical properties in special areas (e.g. dissipation factor or dielectric constant). A standardisation is not possible.

-

-

Yes, BCC Cellpack cable accessories can be used with the cable with (H)EPR insulation, but the highest permissible temperature on the conductor during continuous operation must not exceed 90°C (according to HD 620, IEC 60502-2).

-

-

Yes, CHE/CAE cable terminations can be used with class 5 & 6 conductors according to the cross-section ranges specified in the data sheet. Use cable lugs that are suitable for this class of conductor. CHESK/CAESK cable terminations are differentiated from CHE/CAE by the screw cable lug in the kit. They may not be used with class 5 & 6 conductors.

-

-

Yes, joints can be used with class 5 and 6 conductors according to the cross-section ranges specified in the data sheet. Use compression connectors that are suitable for this class of conductor. CHM joints are different from CHMSV due to the screw connector in the kit. They cannot be used on conductor class 5 and 6.

-

-

The suitability of WAGO's spring clamp technology has been tested and approved for applications using PUR gel as well as for Cellpack's EG and CG cast resin types. There is no experience or test results beyond these approvals as to how the various other sealing materials available from Cellpack affect the plastic material of the clamps and whether the cast resins or gels have any effect on the long-term quality of the contact behaviour of the clamps. The application confirmation for further cast resin types is therefore not currently possible and can only be made after additional tests.

-

-

The manufacturer has not specified any maintenance intervals. Taking into consideration the local pollution and the expected precipitation (cleaning effect), however, we recommend that the operator/responsible person regularly inspects/assesses and, if necessary, removes deposits (sand, salts or other dirt) from the sets.

-

-

The SRAT heat shrinkable tube can be used as a core insulating tube for end closures and as protection against corrosion. It must not be used to protect busbars or to shorten the distances between these busbars. This function has not been tested. It cannot be guaranteed. The SRBB hose is the right solution for this application.

-

-

Whether a shrinkable sleeve can be used for repairing the cable sheath is based on the damage assessment of the cable manufacturer. The shrinkable sleeve is only used for mechanical protection and prevents the moisture ingress. The shrinkable sleeve does not fulfil any beneficial properties for operating E90 cables.

-

-

Deposits in the form of uniform crystallisation on the inner surface of EPDM insulating bodies are process-related degradation products of the peroxide used in the manufacturing process.

There are no negative findings on effects of such crystallisation that would impair the function of the device. Depending on storage temperatures and duration, these crystal formations can occur on all surfaces. In case of very strong crystallisation, we recommend wiping the inner surfaces as part of the inspection and cleaning process prior to assembly in order to avoid influences when screwing in the insulating terminations or placing the insulating body on the entry point.

-

-

Test standard DIN EN 50393 does not contain any test of the entire system for the impact of gases.

Changes in the properties depending on the substance and concentration are also not tested.

-

-

If assembled correctly in accordance with the specifications in the assembly instructions, the cast resin systems are protected against water penetration up to 1m depth.

Test standard DIN EN 50393 contains corresponding tests at a water depth of 1m.

-

-

The term “alkaline earth metals” is a generalisation for alkaline earth metals such as magnesium and calcium that together with water form a chemical solution. This solution can trigger chemical reactions. Different reactions may occur depending on the concentration of a substance in the solution. A solution can generally be summarised under the point “chemical stability”.

-

-

Our cast resins consist of two essential components: a resin and a hardener portion. The hardener of PUR cast resins contains isocyanates (isocyanates are the essential raw materials for producing polyurethanes).

Since they pose health risks that can be minimised if used correctly, an EU restriction has been enforced. This restriction applies to all PUR cast resins (EG, FG, GG, UG, UWR, WG, AMX) from BBC Cellpack.

Extract from a safety data sheet: Due to a restriction on the use of diisocyanates as set out in Commission Regulation (EU) 2020/1149 of 3 August 2022 amending Annex XVII to Regulation (EC) No 1907/2006, the following applies: As of 24 August 2023, appropriate training must be provided prior to industrial or commercial use. Without any specific training, such use is prohibited from this point onwards.

There are a number of providers who also offer this training online and issue a verified certificate immediately afterwards. It depends on the use of the products which training modules are required. Additional information is available from the training providers, among others: FSK – Specialist Association Foamed Plastics and Polyurethanes e. V. ISOPA – European Diisocyanate and Polyol Producers Association

Important note: Fully reacted polyurethanes (= cured cast resin) no longer contain any isocyanates. As a result, there are no health hazards associated with isocyanates. Other sealing materials, such as CG or silicone gels do not contain diisocyanates. As a result, they are not affected by the restriction/training.

-

-

The following conditions must be observed:

1. Instructions for transportation and storage:

Storage conditions

| Temperature range | 0…+50°C |

| Relative humidity range | 0…50% RH |

Short-term storage conditions (up to a maximum of 120 minutes)

| Temperature range | -40...+60°C |

| Relative humidity range | 0…70% RH |

Deviations from these conditions during storage can lead to functional limitations of individual components and, in individual cases, make assembly more difficult or impossible. A malfunction of the product cannot then be ruled out. Repeated short-term exceeding of the permanent storage conditions can also lead to restrictions due to the temperature dependency of individual components (filling material, field control mastics).

2. Instructions for assembly:

Mounting instructions are supplied with each product (they are part of the kit). Temperature range for mounting / installation for these products: 0 to +40°C

3. Operation:

Operating temperature range:

| Straight-through joints (plastic cable e.g. XLPE to XLPE) | is equal to the maximum continuous conductor temperature of the cable at 90 °C |

| Cable terminations (plastic cables, e.g. XLPE) | is equal to the maximum continuous conductor temperature of the cable at 90 °C |

| Transition joints (paper-to-plastic cable) | corresponds to the maximum continuous conductor temperature of the paper cable at 60 °C |

| Straight-through joints (e.g. paper-to-paper cable) | corresponds to the maximum continuous conductor temperature of the paper cable at 60 °C |

-

-

Resistance to chemical effects must always relate to a substance and specific property and their changes. “Good resistance to chemical effects” generally refers to a broad tolerance. Tests with acids (e.g. 10% hydrochloric acid), lyes (e.g. 10% NaOH), polar (e.g. isopropanol / water() and apolar solvents (e.g. transformer oil) are usually a prerequisite.

-

-

The designation FE180 indicates that insulating properties are maintained for 180 minutes in accordance with a corresponding electrotechnical test standard. The designation E90 means that a complete system maintains functional integrity for 90 minutes. This abbreviation stands for special behaviours of the cable system in the case of fire.

-

-

Polyurethane (PUR) cast resins consist of two components, one resin and one hardening component. Elements of the hardening component react more easily with water than with the PUR resin component. The mixture foams on contact with moisture. The electrically and mechanically required properties are not met in this case. Special cast resin systems, such as the UWR cast resin, are available when working in humid conditions.

-

-

The nominal voltage of a cable is the voltage for which the cable is designed and includes the operating characteristics and testing requirements. Based on DIN VDE 0298-3, the nominal voltage is expressed in volts by the ratio of two values Uo/U.

The following applies:

Uo – the rms value of the voltage between an outer conductor and earth (metallic sheath / screening of the cable), conductor-earth voltage.

U – the rms value of the voltage between two outer conductors of a multi-core cable or a system of single-core cables, conductor-to-conductor voltage.

In an AC system, the nominal voltage of a cable must be at least equal to the value for Uo and U of the system. In addition, the IEC regulations also specify the highest permissible voltage Um (maximum voltage) in brackets Uo/U (Um). BBC Cellpack products are labelled with the maximum permissible voltage Um.

-

-

Our cast resin systems have been tried and tested over decades. The electrical and mechanical properties after hardening create a permanent and reliable cable connection. We provide a wide range of cast resins for multiple application areas.

-

-

This new technology combines easy handling, unlabelled material and indefinite storage periods. The electrical properties after hardening create a permanent and reliable cable connection. We recommend to keep a minimum wiring distance between the terminals / cores and walls of the branch boxes.

-

-

Our heat shrinkable products have been tried and tested over decades. The electrical and mechanical properties after cooling down create a permanent and reliable cable connection. Heat shrinkable products can be ordered for stockpiling as they can be stored for indefinite periods.

-

-

The CE marking is applied to products intended for the internal European Union market. The manufacturers apply such labels to declare that the labelled electrical equipment complies with the applicable health, safety and environmental protection requirements for products in the European Economic Area (EEA).

The CE marking is in accordance with Directive 93/68/EEC and is intended for usage within certain voltage limits. In addition, a product may only feature a CE marking in accordance with EC Directive 765/2008 if the product requirements are defined in at least one corresponding EU directive. Examples of such directives include the Low Voltage Directive (2014/35/EU), the EMC Directive (2014/30/EU), the ATEX Directive (2014/34/EU) and the Radio Equipment Directive (2014/53/EU).

The CE declarations of conformity for low-voltage products are freely available in the download area of our online product catalogue. If none of the directives are applicable, the CE marking is not applied to the product in accordance with the applicable laws. CE conformity is also not issued for such products.

The BBC Cellpack medium-voltage sets listed below do not fall under the EU directives requiring CE marking: CHE… , CHM… , CAE… , CAM… , CGS… , CTS… , CWS… BBC Cellpack medium-voltage sets are nevertheless developed in accordance with the applicable international standards and are subjected to numerous checks and tests during the development process as well as during production to ensure safe and reliable operation, e.g: CENELC HD 629.1, CENELEC HD 629.2 or IEC 60502-4.

-

-

The hardening time describes the time required for hardening 100% with the mechanical properties of components A and B. The pot life is a standardised term which colloquially is defined as processing period. Reactions may be quick or slow, depending on different temperatures.

-

-

For low voltage, a joint or cable termination must be used for recreating the basic insulation and sheath. Cast resins, silicone gels or heat shrinkable tubes can be used to do this.

The insulating parameters are much higher in the medium voltage range. The electrical field also has to be treated. Field control elements are used to do so as well as a special system component geometry.

-

-

Differences between CENELEC HD 629.1 S3:2019 and IEC 60502-4:2010 type tests

Test parameter | CENELEC HD 629.1 | IEC 60502-4 |

DC Voltage | not required | 4 U0 / 15 min dry |

| Heating cycles (separable connectors, straight joints/ terminations) | 63 in air and 63 under water / 126 cycles | 30 in air and 30 under water / 60 cycles |

Partial discharge | max 10 pC at 2 U0 | max 10 pC at 1,73 U0 |

Dynamic short-circuit test | One short-circuit at Id only for 3 core (depending on the test sequence) | One short-circuit at Id for 1 core and for 3 core (depending on the test sequence) |

Id short-circuit current (initial peak value) in the conductor;

-

-

The recommended processing temperature of POWER GEL is between +15 °C and +30 °C, whereas the thermal stability is between -40 °C and +150 °C.

-

-

The low voltage heat shrinkable tubes must meet the requirements of the DIN EN 50393 standard. This standard gives a detailed description of test methods and requirements for sets with a nominal voltage of 0.6 / 1.0 (1.2) kV. The standard properties and requirements for heat shrinkable tubes are contained in the DIN IEC 60684 standard (Part 1: Terminology and general requirements; Part 2: Test methods; Part 3: Requirements for individual tube types).

The allocation of protection classes (protection types) is part of DIN EN 60529 (VDE 0470). According to this standard, the scope of the protection provided by a housing against access to hazardous components, penetration of solid contaminants and/or water penetration has been proven with standardised test methods. In both cases (low voltage heat shrinkable cable joints / tubes), there is no additional housing, which makes it impossible to test the protection class.

-

-

The calculated possible voltage on capacitive measuring point is between 0,08 … 0,5 Uo, depending on capacity ratio (conductor to measuring point and measuring point to earth). In any case, even minimum at 6/10(12)kV , voltages can be reached up to 500V.

So open measuring point is always dangerous to life! Since measuring is object of system operator, BBC Cellpack do not have safety procedure beside normal safety procedure for handling of electrotechnical equipment.

It must be clear that the voltage on measuring point is dangerous.

-

-

BBC Cellpack Electrical Products has been selling cable accessories for low and medium voltage applications for more than 40 years. Based on feedback from our customers and their records, as well as the very low number of complaints, it can be stated that safe operation of our cable accessories for low voltage and medium voltage applications is achievable for a period of more than thirty years.

Important note on warranty:

BBC Cellpack Electrical Products is only supplying components (kit) with installation instructions describing their assembly steps. The assembly of the cable accessories itself is not carried out by BBC Cellpack, but by the customer or an assembly company appointed by the customer. In general, in accordance with legal requirements, BBC Cellpack Electrical Products can only provide warranty for the components (kit) supplied, but not for the assembled cable accessories, as BBC Cellpack Electrical Products has no necessary influence on the quality of cable preparation and assembly of the cable accessory or their operation in the network. The cable accessories are free from material defects if they are suitable for the use stipulated in the contract at the time of handover to the customer. The specification of the expected lifetime does not represent a guarantee, assurance, quality agreement or other commitment binding on the seller and also does not represent an extension of the warranty period beyond the warranty within the framework of the statutory periods.

Description of various factors influencing the service life of cable accessories:

There are several factors that can negatively affect the service life of a cable accessory. In our experience, these include normally and not exclusively cable preparation and assembly, network operation or the network conditions themselves, as well as the storage of the kit or the temperature at which the installation is carried out. Due to the many possible influencing factors, this list does not claim to be complete. A legally binding general statement on the service life by BBC Cellpack Electrical Products is therefore not possible and will not be given by us. Influence of cable preparation and assembly on the service life of cable accessories: Basic requirement to achieve the lifetime are careful and clean cable preparation in accordance with the state of technology, but also careful and conscientious compliance with the work steps specified in BBC Cellpack installation instructions. In addition to this requirement, only components supplied from the manufacturer as part of the kit or recommended or approved by the manufacturer, for example connectors qualified according to IEC61238, may be used for proper installation and function of the product. For proper installation as a prerequisite for a long service life, user training is recommended for new products or technically complex solutions.

Influence of network operation or network conditions on the service life of cable accessories:

The service life of a product always depends on the conditions of the power supply network acting on the product. BBC Cellpack Electrical Products cable accessories are type-tested in the low-voltage range in accordance with or based on the EN50393 standard, and in the medium-voltage range in accordance with or based on the HD629 standard. Electrical, mechanical or thermal stresses exceeding the requirements of these standards may have significant effects, i. e. lead to a reduction in the service life of the cable accessories. Thus, no estimate of the possible or remaining service life can be made if, for example, effects of short circuits or transient voltage increases due to switching operations or lightning surge voltages have occurred. The application of the aforementioned standards is not legally binding. However, even if all standards are applied, not all of the influencing factors that may affect the service life of cable accessories are conclusively.

Influence of the storage conditions of the delivered product as well as the temperature during installation on the service life of cable accessories:

In the question of proper storage conditions, a distinction must be made according to the technology used: Components and products using cast resin, gel or cold shrink technology or other cold-applied products may be subject to restrictions on storage time, restrictions on storage conditions or recommendations on installation conditions. Corresponding information on the maximum permitted storage time, the recommended storage conditions and the recommended temperature range for assembly can be found in the product documentation and is also listed in brief form on the product label/label.

-

-

The tightening torque is 30Nm.

-

-

Shielded plug or screw cable connectors with and without metal housing are earthed materials that can be safely touched during fault-free operation if they have been earthed and installed properly.

We generally recommend not touching any live separable cable connectors as it is not always apparent from the outside of they are operating properly.

-

-

1. Instruction of transportation and storage:

Storage conditions

| Temperature range | 0...+40°C |

Deviations from these conditions during storage can lead to restrictions in the function of individual components and in individual cases make assembly difficult or impossible.

2. Instructions of Mounting:

3. Operation:

Operating temperature range (always dependant also on the cable criteria):

| SMH4 - Heat shrink joints for LV cables – operating temperature range of heat shrink tubes of the kits | -40°C up to +120°C |

| SKH – Heat shrink end caps | -40°C up to +100°C |

| SEH - Heat shrink spreader caps | -40°C up to +100°C |

| SRH3 - Heat shrink thick wall tube | -40°C up to +120°C |

| SRMAHV - Heat shrink repair sleeve | -40°C to +120°C |

The more information on individual product characteristics can be found in the product data sheet.

-

-

1. Instructions of transportation and storage:

Storage conditions

| Temperature range | 0°C... + 50°C |

| Relative humidity range | 0°C... 50% RH |

Short-term storage conditions (up to maximum 120 minutes)

| Temperature range | -40°C... + 50 °C |

| Relative humidity range | 0°C... 70 % RH |

Deviations from these conditions during storage can lead to restrictions in the function of individual components and in individual cases make assembly difficult or impossible. A malfunction of the product is then not excluded. Even a repeated short-term exceeding of the permanent storage conditions can lead to restrictions due to the temperature dependencies of individual components (filling material, field control mastics).

2. Instructions of Mounting

Mounting instructions are provided with each product (it is a part of the kit). Temperature range for mounting / Installation for these products: 0 to +40°C

3. Operation

Operation temperature range (always dependant also on the cable criteria):

| Straight-through joints (polymeric insulated cables e.g. XLPE to XLPE | is same as the maximum continuous conductor temperature of cable à 90 °C |

| Cable terminations (polymeric insulated cables e.g. XLPE) | is same as the maximum continuous conductor temperature of cable à 90 °C |

| Transition joints (paper to polymeric insulated cables) | is same as the maximum continuous conductor temperature of paper cable à 60 °C |

| Traight-through joints (e.g. paper to polymeric insulated cables) | is same as the maximum continuous conductor temperature of paper cable à 60 °C |

-

-

The requirements placed by the customer/user on the end product and the requirement for its proper function in its operating environment are important.

In general, halogen-free heat shrinkable components can also be used on cables that contain halogen (PVC) and heat shrinkable components that contain halogen (e.g. flame-retardant hoses) can generally also be used on halogen-free cables (PE, XLPE).

-

-

- What is the system voltage? AC or DC voltage?

- Which type of cable accessories is required? And for which application is it used? (Example: cable termination for a switchgear or for a motor terminal box)

- Check the cable data and compare it with the description of the selected cable accessories

* Conductor material and conductor cross-section (copper or aluminium)

* Number of cores, conductor cross-section, conductor shape and conductor class

* Screen type (wire, tape, al-foil bonded etc.)

* Diameter over insulation and over cable sheath

* Material of insulation and cable sheath

* Armouring – yes/no

* Concentric conductor (Ceander) – yes/no - Where is it installed? (e.g. explosion-proof areas, mining applications, fire precautions and water depths, etc.)

- In what ambient conditions (temperature, sand and dirt, etc.) will it be installed?

- Choosing of preferred connection technology (screw, crimp)

- What ambient conditions? (Temperature, sand and dirt, etc.)

- Select a product according to voltage (system and cable) and current

- Which standards and approvals are relevant?

- If a specific adjustment is required, please consult your contact

-

-

The recommended storage temperature for PUR cast resin products offered by BBC Cellpack is between 15°C and 35°C.