-

-

The SHE house connection point is not suitable for feed-through in floor slabs.

-

-

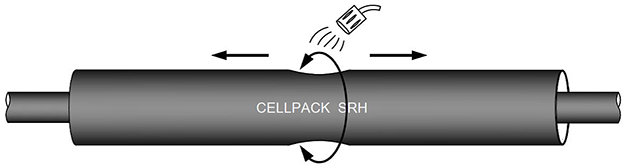

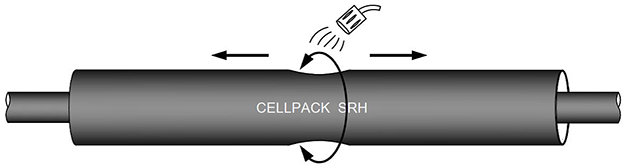

Heat shrinkable components are components that shrink back to their original production state when heat is applied, such as spreader caps, end caps, hoses, or sleeves. A hot-air blower can be used for shrinking. The heat input, however, is lower compared to a gas burner. This prolongs the duration of the shrinking process. The settings and nozzle must be individually selected depending on the hot-air blower used. It is important to make sure that the surface of the shrinkable tube is not burned.

If it is a hose with hot melt adhesive (SRH...), the adhesive will slowly flow out at both ends. Uniform wall thicknesses and straight labelling are important indicators for correct shrinkage.

-

-

Our joints go through extensive tests, such as test standard DIN EN 50393. We thus guarantee that our joints function permanently and are safe. We seriously discourage you from making your own joint so that you do not have to assume responsibility.

-

-

It has to be remembered that the cable cross-section and minimum diameter across the insulation falls within the specified range for the set. The reverse is excluded. In most cases, the applicable system voltages are specified in the documentation available and provided.

-

-

The responsible person in the network is responsible for deciding whether a cable sheath can be repaired. This depends on the damage and the properties the cable sheath satisfies. In general, a cable may only be repaired with a sleeve if the damage affects only the outer cable sheath. If additional damage to the core insulation is detected, repairs by means of a sleeve are not permitted. The cable must then be repaired as a complete system, either with additional insulating and sealing components over the damaged core(s) or, if necessary, by installing a straight-through joint over the damaged cable section.

If it decided to use shrinkable sleeves, the sleeve should be selected according to the values mentioned in the catalogue. The operating voltage of the cable is not the deciding factor when selecting the right sleeve. The function of sleeves is described as follows - restoration of the outer cable sheath in its three functions insulation, protection against moisture and mechanical protection.

-

-

Cellpack SR(H), SRAT, SRBB hoses do not contain chlorine (or any other halogen-containing materials), sulphur, heavy metals or substances that are hazardous to health. A corresponding RohS and Reach conformity confirmation is available for the respective component.

-

-

Firstly, position the shrinkable tube. Initially set the blow torch to a soft yellow flame. Now start the heating process from the centre and radiating outward. Continue this movement whilst initially shrinking one full side. Now change back to the centre and repeat the process on the other side.

If the tube contains hot melt adhesive (SRH...), the adhesive slowly escapes at both ends. Important indicators that the shrinking process has been completed correctly are even wall strengths and straight labelling. Below is an image from straight-through joint assembly instructions:

-

-

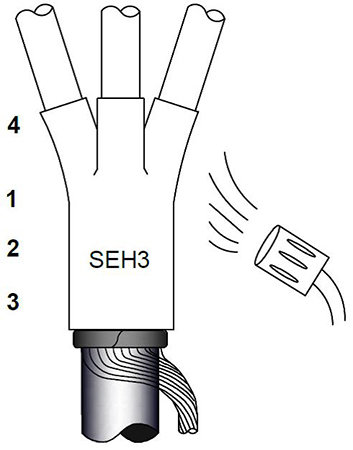

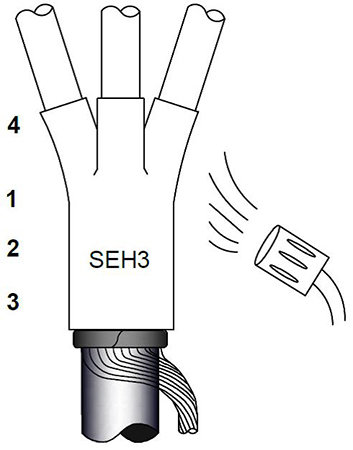

Firstly, position the spreader cap on the cable joint. Initially set the blow torch to a soft yellow flame. Now start heating up the interstice (1) radially. Continue this movement whilst shrinking the shaft (2+3) toward the cable sheath. Now change back to the shaft and evenly shrink the fingers (4) toward the core; also heat up the inside of the splice. The adhesive slowly escapes at the end of the shaft and the spreader fingers after a short period. Important indicators that the shrinking process has been completed correctly are even wall strengths and straight labelling.

-

-

A tube is initially extruded from polyolefin pellets. Depending on the type of tube, the hot melt adhesive is introduced in this step (co-extruded). The tubes are then electron beam cross linked. This changes the molecular structure and the tubes receive a “memory”. In another work step with heat supply, the tube is expanded to the required diameter, then cooled down and cut. When heating up, the tube “remembers” its original state and shrinks back.

-

-

This is used for easily feeding cables and cores through walls in buildings.

Simply put, it is a shrinkable tube that is positioned on a formative metal spiral. Once installed, the cable is pushed through the duct in the house and sealed by simply heating up the ends of the house duct. This is the assembly process:

First drill a hole through the brickwork. It is recommended to refer to the BBC Cellpack data sheet to ensure that the right drill bit with the right diameter is being used. The cable centering aid can be used for aligning the house connection point. When the distances are correct, the sealing compound can be prepared. Like the cast resin, it is mixed in a two-chamber bag but has a much quicker reaction time. A homogenous sealing is now created with a spatula. Due to the shorter processing time, a separate bag can be used for the inside and outside.

-

-

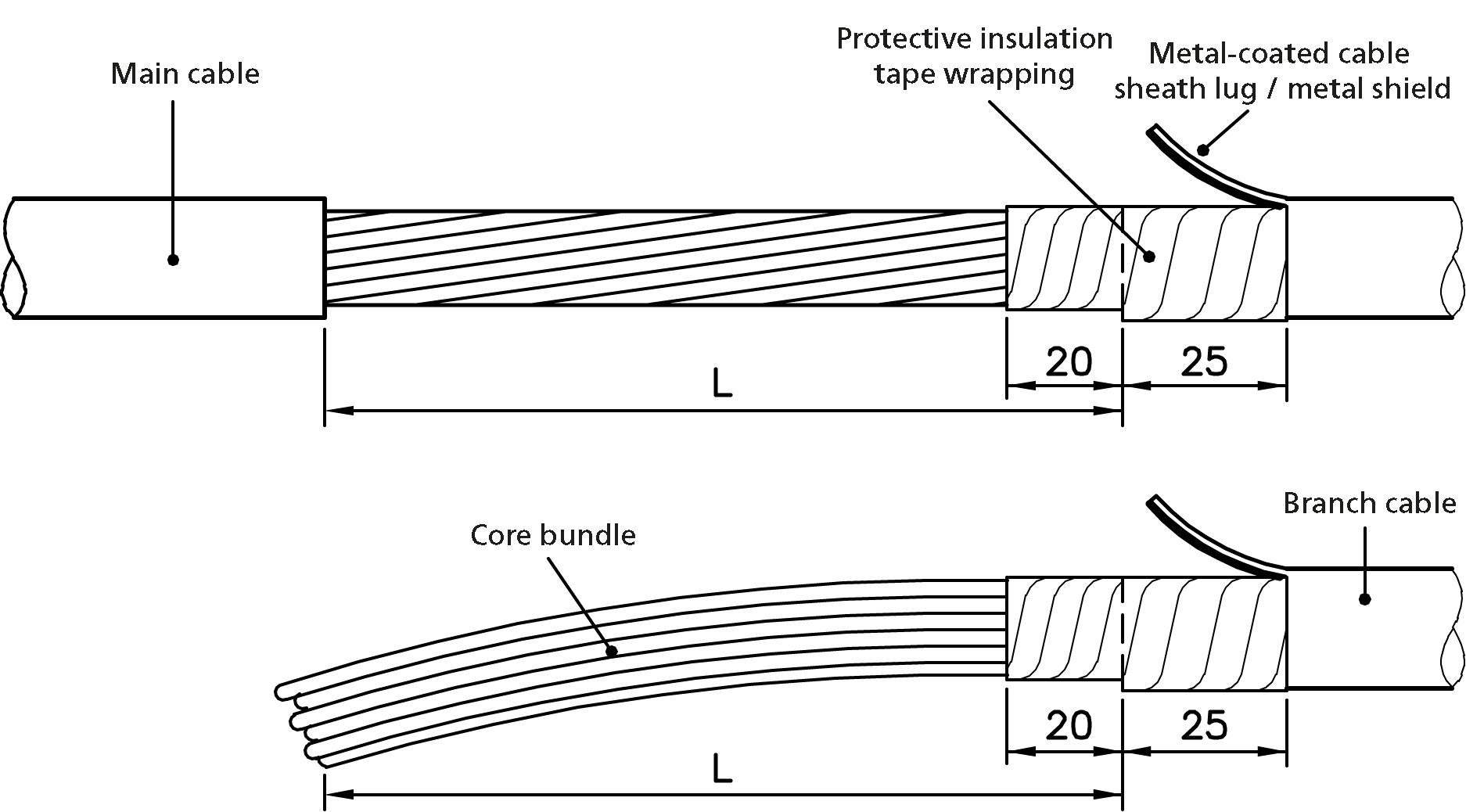

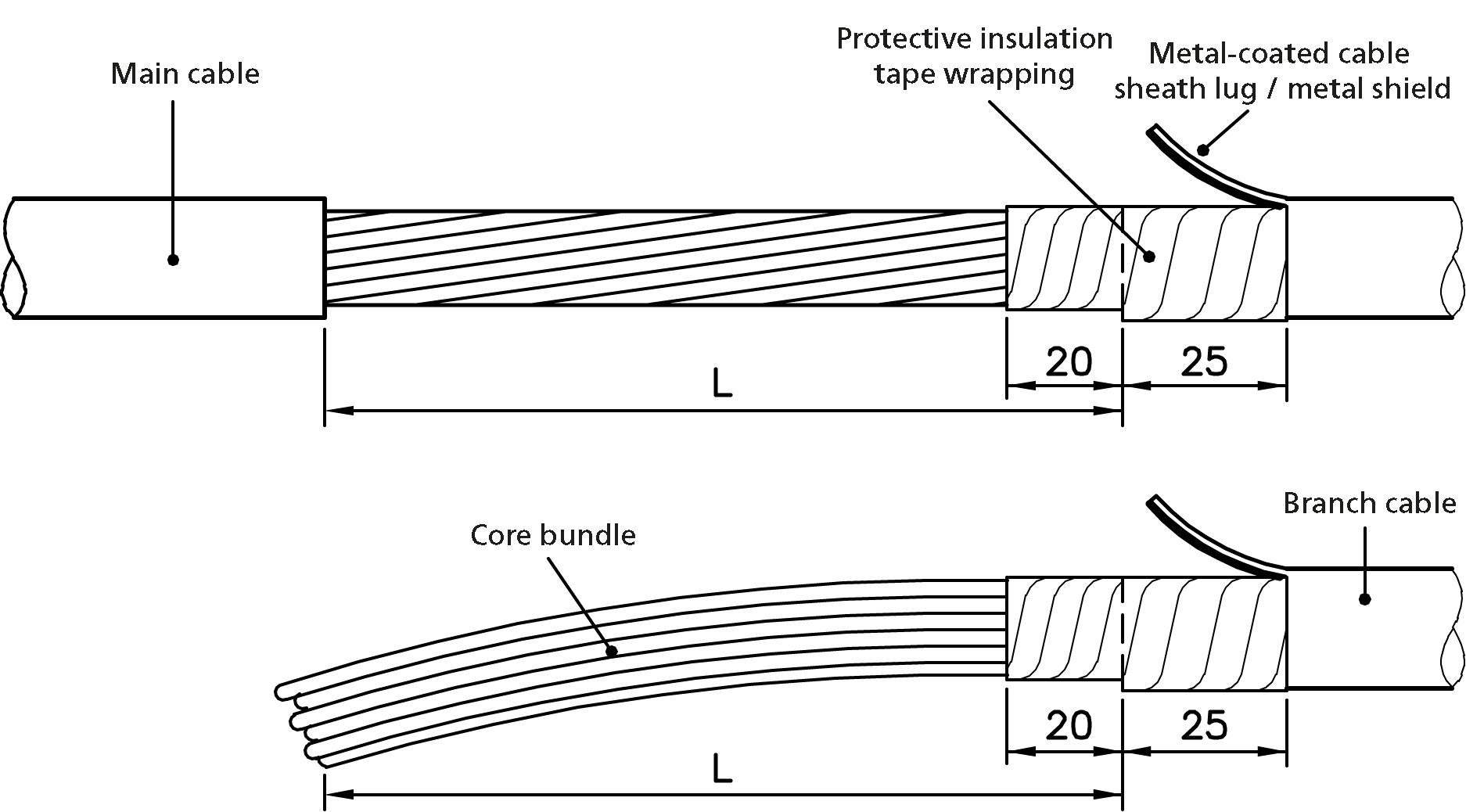

In the assembly instructions for the VASMI and SMHF telecommunication joints, this step is described as follows:

A) Preparing the cables

Overlap the cables as shown in drawing:

The cables are prepared exactly like the straight-through joints, depending on cable type.

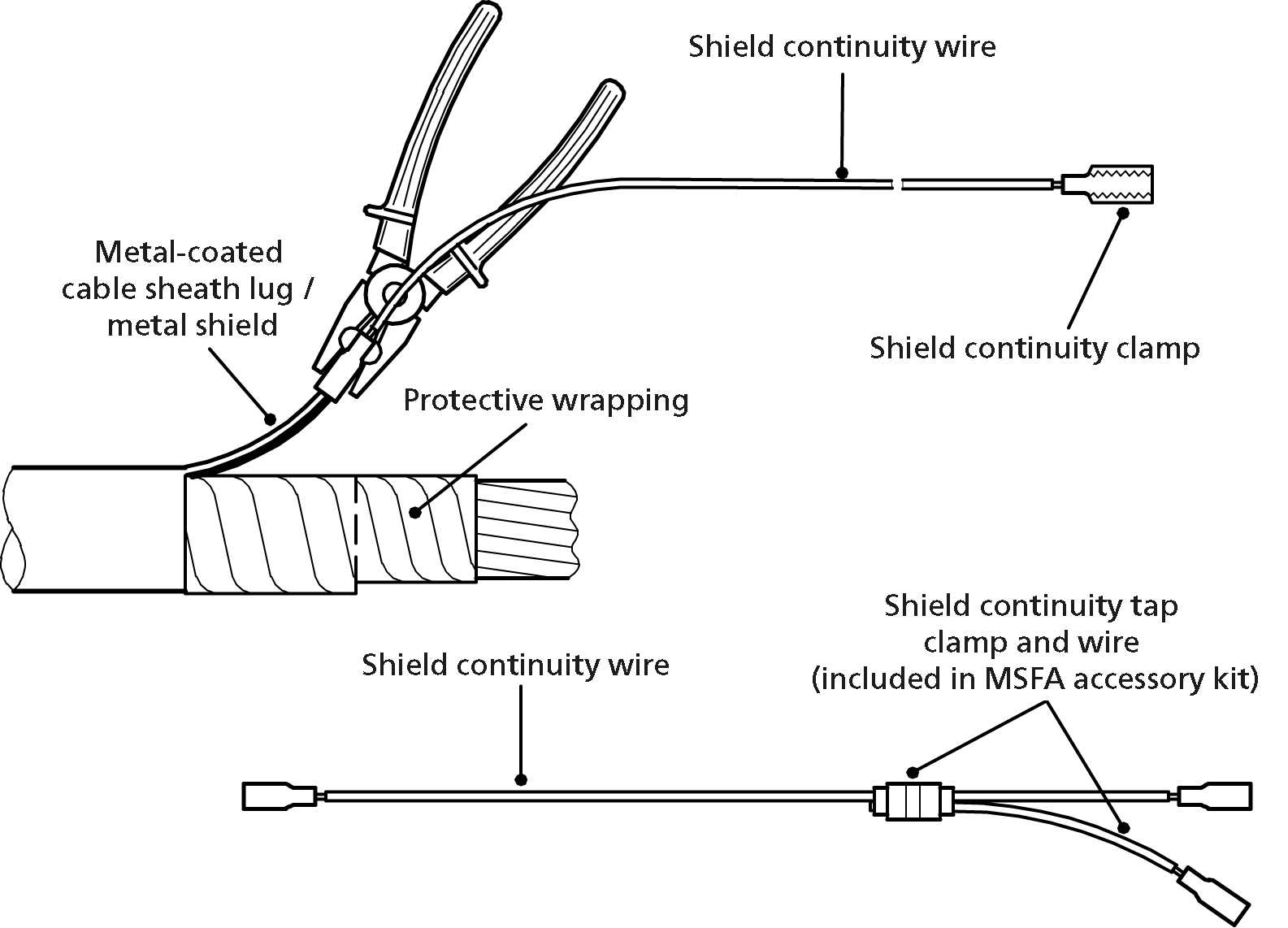

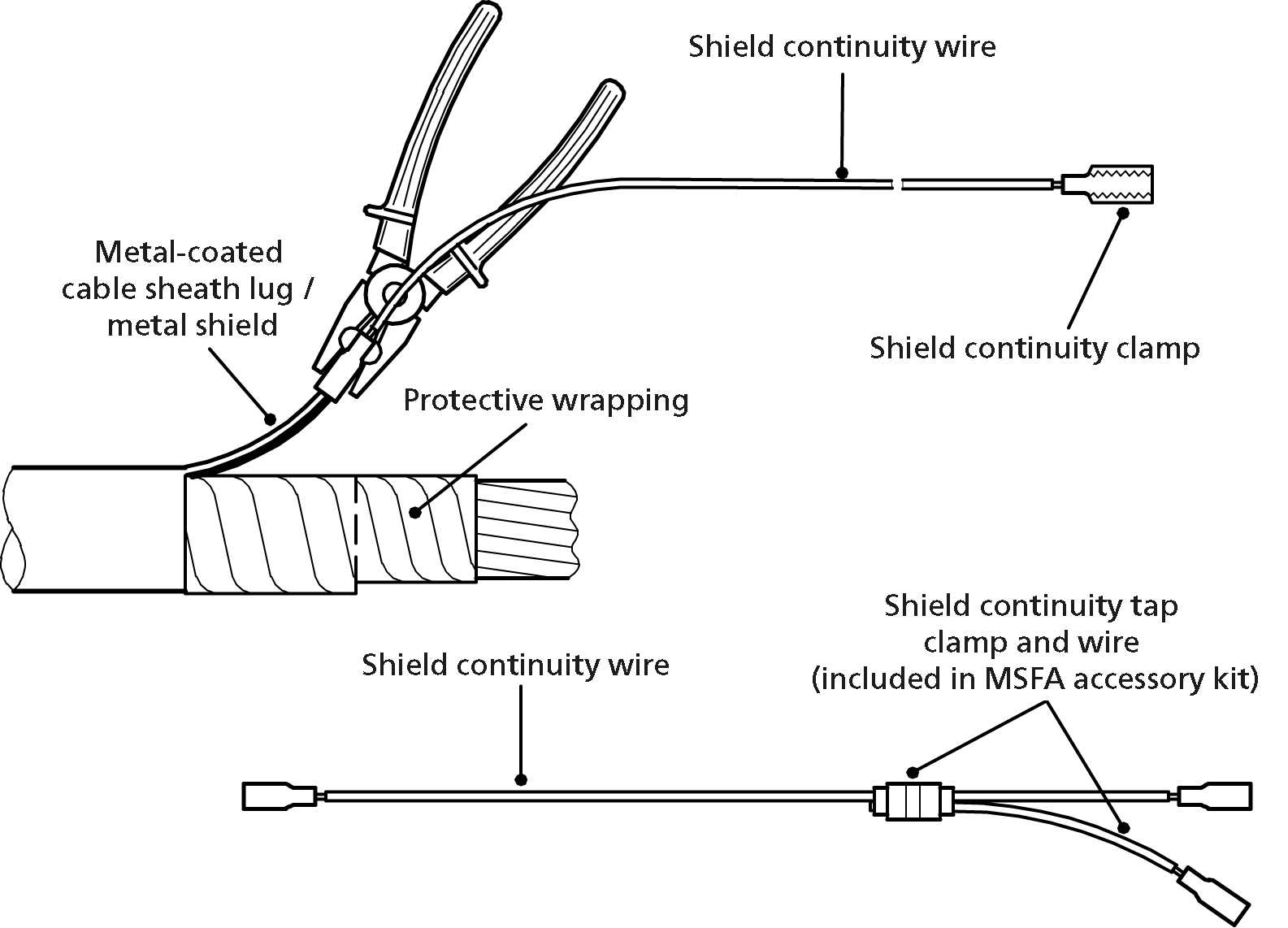

B) Screen connection

Create screen connection like the straight-through joint.

Assemble screen connection branch clamp and wire (take from MSFA and assemble according to the assembly instructions).

The MSFA accessories set is only required for branch joints.

-

-

The heat shrinkable kits offered by BBC Cellpack are suitable for concealed installation. We do not recommend using individual tubes without hot-melt adhesive, since in this case, there is no protection against the penetration of moisture and the insulating function of the hose over the offset cable cannot be fulfilled.

-

-

The SRAT heat shrinkable tube can be used as a core insulating tube for end closures and as protection against corrosion. It must not be used to protect busbars or to shorten the distances between these busbars. This function has not been tested. It cannot be guaranteed. The SRBB hose is the right solution for this application.

-

-

Whether a shrinkable sleeve can be used for repairing the cable sheath is based on the damage assessment of the cable manufacturer. The shrinkable sleeve is only used for mechanical protection and prevents the moisture ingress. The shrinkable sleeve does not fulfil any beneficial properties for operating E90 cables.

-

-

Our heat shrinkable products have been tried and tested over decades. The electrical and mechanical properties after cooling down create a permanent and reliable cable connection. Heat shrinkable products can be ordered for stockpiling as they can be stored for indefinite periods.

-

-

The low voltage heat shrinkable tubes must meet the requirements of the DIN EN 50393 standard. This standard gives a detailed description of test methods and requirements for sets with a nominal voltage of 0.6 / 1.0 (1.2) kV. The standard properties and requirements for heat shrinkable tubes are contained in the DIN IEC 60684 standard (Part 1: Terminology and general requirements; Part 2: Test methods; Part 3: Requirements for individual tube types).

The allocation of protection classes (protection types) is part of DIN EN 60529 (VDE 0470). According to this standard, the scope of the protection provided by a housing against access to hazardous components, penetration of solid contaminants and/or water penetration has been proven with standardised test methods. In both cases (low voltage heat shrinkable cable joints / tubes), there is no additional housing, which makes it impossible to test the protection class.

-

-

The requirements placed by the customer/user on the end product and the requirement for its proper function in its operating environment are important.

In general, halogen-free heat shrinkable components can also be used on cables that contain halogen (PVC) and heat shrinkable components that contain halogen (e.g. flame-retardant hoses) can generally also be used on halogen-free cables (PE, XLPE).

-

-

The SR1F and SR1F3 tubes are permitted in accordance with UL. Both tube types are listed in the UL list under document number E172094.

-

-

There are currently no sets available for EX areas due to normative changes.